Industrial Air Compressor Solutions in Florida: Success Stories and Reviews

Comments Off on Industrial Air Compressor Solutions in Florida: Success Stories and Reviews

Compressed Air Systems offers compressed air solutions in Florida, and we’re proud to provide high-level service to ensure your systems are operating efficiently.

Our Success Stories

Lockheed Martin: Melbourne, FL

Like many companies, Lockheed Martin wanted to lower utility costs in their facility. Their nitrogen system was costing more than $20,000 a month in storage, fees, and more.

The engineer in charge of the project wanted to replace that system with an oil-free air compressor and brought the idea to CAS. Sales Manager Kyle Randall took on the assignment and quickly realized there wouldn’t be enough space to install the compressor in the facility. This was going to require a custom solution.

CAS delivered a turn-key solution:

- Randall and the CAS team designed a portable room to accommodate the oil-free system

- The system performed as intended from the first day

- When tested by third-party lab technicians, no hydrocarbons or particles were found in the air

- It paid for itself within four months

Maaco Auto Body Shop: Orlando, FL

Meanwhile, at Maaco Auto Body Shop, their 30-horsepower air compressor was not performing reliably. The compressor room was too hot; the heat wasn’t being properly ducted away from the area.

Since Maaco had worked with CAS before, they knew we could help them. Jeff Guzzo, our Orlando area sales engineer, suggested two 15 hp Kaeser SM15 air compressors as an alternative to Maaco’s aging system:

- One compressor was capable of supplying enough air on a daily basis

- The second compressor was to serve as a backup, which would engage as needed

- The team also made the appropriate improvements to the ductwork

- Maaco has saved about $300 per month with the CAS system

Reviews From Our Florida Customers

At CAS, we are proud of the work we do and love knowing our customers are happy. These are just a few of our Florida clients’ reviews:

Samuels Auto Corp: Sanford, FL

“Your technician, Pete, went above and beyond for us. My machine was on its last leg and he took all the extra time to restore it as best as possible. He took the time to explain everything in detail. He did an amazing job!”

Environmental Services Department Company: City of Largo, FL

“We were having issues with our aging air compressor and in need of replacement. We searched compressor companies online and found Compressed Air Systems Inc. located in Tampa, FL. After calling the number, I was immediately connected to a salesperson—Bo Wenrich of Compressed Air Systems, who showed up at my location within an hour.

The inside sales rep, Jack, stayed on top of all communication, making sure the unit arrived on time and had delivered to the location in Tampa for all to be coordinated. Compressed Air Systems took care of all coordination between a Contracted Electrician and installation group.

I would recommend Compressed Air Systems to anyone…looking for a Quality Turn Key Experience!”

The Hill Group: Vero Beach, FL

“I wanted to make you aware that your installation crew and Levi Combs were professional on every level. They did an outstanding job installing my new Kaeser compressor, tank, and dryer.

The 15 horsepower Kaeser with dryer and 400 gallon wet tank is truly amazing. From the ease of operation to how beautifully quiet the Kaeser is, down to the air quality has surpassed my expectations. I have done my research on compressors and wasn’t going to settle until I had the best. I now know my research and time has paid off.”

Contact Us About Our Air Compressor Solutions

Since 1963, CAS has been providing compressed air solutions in Florida. Over the years, we’ve enjoyed the opportunity to serve many happy customers, and we look forward to continuing this tradition of top-notch customer service and custom solutions. For a personalized review of your current system, we invite our Florida customers to sign up for a free walk-through consultation to learn more about how to reduce costs and improve efficiency.

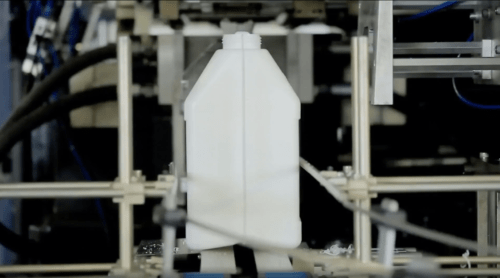

Compressed Air System Capabilities for the Plastic Industry

Comments Off on Compressed Air System Capabilities for the Plastic IndustryThe plastic industry in the United States accounts for $380 billion in shipments every year and has created 885,000 domestic jobs. It’s the third-largest manufacturing industry in the country.

Industry-leading plastic manufacturing plants use air compressors because they are the best at providing precise, reliable, and efficient power to manufacture high-quality plastics safely and consistently. In fact, air compressors have become the standard tool for delivering power.

Why Use Air Compressors in the Plastic Industry?

Plastic manufacturing requires precise operations to ensure the product holds a strong, durable shape. Every facility’s power delivery system must be fine-tuned, so it can operate during delicate stages of the process. At the same time, plastics plants need consistent access to energy-efficient power solutions that allow them to operate within stringent efficiency regulations.

Air compressors strike the balance between three competing requirements in plastic industry facilities: precision, reliability, and energy efficiency.

Precision

While current technology can minimize fluctuations in electrical currents, it can’t stop them entirely. Pneumatic air compressors stabilize the flow of power into equipment and processes by absorbing the fluctuation. Air compressors can also be tightly controlled to deliver precise levels of power and pressure at each manufacturing stage.

Reliability

Air compressors are a main utility for plastic processing plants and having a premium air compressor is worth the investment. Without interrupting production of their compressor air demands, a second compressor is vital for reliability.

For example, in dusty or dirty manufacturing conditions, air compressors can perform more reliably than other tools. A properly maintained air compressor will perform more reliably. They can also maintain consistent performance during temperature fluctuations and adverse weather conditions when properly equipped with correct options.

Energy Efficiency

Due to increasing concerns about energy production, greenhouse gases, and climate change, manufacturing facilities are under intense pressure to operate more efficiently. Air compressors help generate power in a way that is both cost-efficient and compliant with energy consumption regulations.

Finding the Proper Air Compressor for the Plastic Industry

Every plastic manufacturing plant is slightly different and operates in varied conditions, which means they need the right air compressor for their unique solutions. Selecting one while constructing a new manufacturing facility or retrofitting an existing plant for air compression power is absolutely essential to maximize all the benefits of pneumatics.

Some important considerations include:

After the Sale Support

You need an air compressor that is easy to use and shows immediate results after installation. It’s also important to find manufacturers that offer warranties, service guarantees, and support after the initial purchase and installation. Look for manufacturers that:

- Offer diagnostics, support, and maintenance

- Have easy-to-reach customer service lines

- Have a wide distribution network for parts and servicing

Quality Construction

Air compressors need to have high-quality construction to remain durable and energy-efficient throughout years of industrial use. They need:

- Innovative design

- Totally enclosed fan cooled (TEFC) motors with class F insulation

- Service friendly construction

- Guaranteed efficiency

- Magnetic wye-delta reduced voltage starting

- Efficient separator system

- Low sound and vibration

- CAGI (Compressed Air & Gas Institute) certified performance

- Monitoring and maintenance controllers

Looking for well-made air compressors, even if they have a higher initial cost, can save your facility time and money on repairs, downtime, leakages, and energy waste.

Smart Analytics

No matter how large your facility is, employing your air compressor with smart analytics technology can help it stay on top of potential malfunctions, leaks, and surges in energy consumption. Smart systems gather data about:

- Potential areas with wasted electrical use

- Developing strains in the system

- Aggregate electrical consumption to ensure your facility is staying compliant with energy use regulations

Contact Compressed Air Systems Today to Learn More

If you’re constructing a new plastics manufacturing facility or retrofitting a plant to use air compressors, contact Compressed Air Systems today. Our team will help you find the best air compressor and control systems for your needs.