Air Receiver Tanks | Air Compressor Tanks

The right air receiver tank or air compressor tank not only enables air compressors to work efficiently but also provides a temporary storage vessel for pressurized air. Due to their critical importance to your operations and the high pressures they contain, air compressor tanks must be strong, durable, and rated for their intended application.

At Compressed Air Systems, we supply customers with strong, long-lasting air receiver tanks and air compressor tanks. Learn more about their role and how to optimize your operations with the right air tank.

What Is an Air Receiver Tank?

Air receiver tanks hold compressed air in reserve for peak usage times so facilities don’t have to slow operations or prioritize certain functions over others. The tank holds between six and 10 times the air of the system’s flow rate. For example, an air compressor with a 25 scfm flow rate at 100 psi has an air receiver tank capacity of at least 150 cubic feet.

Along with providing air ready for use during peak intervals, air receiver tanks provide several other benefits:

- Moisture removal: Air tanks cool the air within the compressor system to remove water, which could otherwise cause corrosion and jeopardize the integrity of the system or end products.

- Pulsation reduction: A reciprocating compressor or downstream cyclic process typically produces pulsation or vibration. Air compressor tanks can reduce or largely eliminate those pulsations in the system.

- Improved torque and speed: Air tanks can improve the torque or speed of pneumatic-powered equipment by helping to maintain a continuous pressure level.

- Supplementing high-flow applications: The tanks can supply compressed air to meet the needs of high-flow-rate applications as well as multiple sources of demand.

These benefits can help improve the efficiency of your facility’s operations, by increasing the capacity of your systems and minimizing pressure fluctuations.

Air Receiver/Air Compressor Tank Sizing

How to size an air receiver tank? No matter the use, it’s important to size it to your needs. You size a tank based on the compressor output, system size, and air demand cycles. One method to estimate the receiver size is this formula:

V = (Q x Pa) / (P1 + Pa)

V = receiver size in cubed feet

Q = compressor output in cfm

Pa = standard atmospheric pressure in psia

P1 = compressed pressure in psig

Compressed Air Systems can help you with air tanks as an authorized Kaeser and Powerex dealer. We offer some of the highest-quality epoxy-coated tanks on the market today. Choose from both new and used models to get the quality you deserve while still staying within your budget.

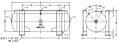

Ranging in volume from 30 to 8,000 gallons, we have air receiver tanks to suit any need. Plus, if you’re not sure which size is right for you, the systems specialists at our facility can advise you and help you figure out which air receiver tanks fit your requirements.

Why Do You Need an Air Receiver Tank?

While air compressors don’t strictly need air receiver tanks or air compressor tanks to function, there are several reasons why facilities might consider installing them. Consider the following improvements these tanks can provide:

- Improved efficiency: Without an air receiver tank, air compressors undergo more loading and unloading cycles, which means the compressor works harder and consumes more energy. This can increase wear on your unit and make the air compressor run down faster. Load/unload cycles depend on the fluctuation of demand in your facility, but by adding a tank, you can minimize these cycles and extend the lifespan of your unit.

- Extended service life: Air receiver tanks function as a buffer between the air pressure fluctuations caused by changing demand levels and the compressor itself. Thus, tanks store compressed air within a stable pressure range before it enters the piping system.

- Space savings: Some air compressor packages come with a tank and can save space. If you have a crowded facility, tank-mounted units are often more space-efficient and more cost-effective. However, tank-mounted air compressor options are only available for sizes up to 26 kW or 35 HP, as larger units become too top-heavy and unsteady.

What Pressure Should My Air Receiver Be?

It’s important to keep your air receiver tank at the right pressure level. Simply increasing the tank pressure does not translate to more air for your processes. On the contrary, as pressure increases, flow decreases.

Facilities should base their tank pressure levels based on their compressor’s output pressure, with the tank at a slightly higher pressure level. For example, if you have a fixed-speed air compressor set at 125 psig, the air receiver tank should be rated for at least 150 psig. If the compressor is at 175 psig—the standard maximum for variable-speed air compressors—the air receiver tank should accommodate 200 psig.

As a built-in safety mechanism, your air receiver tank should also come with a pressure relief valve that releases excess pressure if the tank gets to its maximum pressure. In addition, your system should have pressure regulators at the air receiver tank or the final point of use to ensure both the pressure levels and flow rates are at acceptable levels.

Learn More About Air Receiver and Air Compressor Tanks

Call or contact us today for more information to find out how we can help you with your system. We can also provide you with a wide selection of vital products, including 5-gallon, 30-gallon, and 80-gallon products; oil-free compressors; continuous duty options; thread floor flanges; air blow guns; L port valves; 90-degree elbows; stainless steel vacuum gauges; and even a portable carbon monoxide monitor.

Compressed Air Systems can provide the highest-quality epoxy-coated air receiver tanks to suit your specific needs. Choose from old and new models that meet your budget. Our wide selection of receiver tanks includes 5-gallon, 30-gallon, and 80-gallon products.

Contact us today for more information about air receiver tanks that fit your requirements.