Amusement Park

One of the largest amusement parks in the world entrusted Compressed Air Systems to assist in the engineering of the newly renovated fire works show. Instead of using high pressure air compressors we installed low-pressure high-volume Airtech blowers, saving them thousands by reducing the total HP used and lowering electrical costs.

Glass Company

To run their autoclave efficiently a national glass company needed to double their air usage twice per day for three hours. A variable speed Kaeser Sigma Frequency Control unit was used to meet their daily demands. Once the autoclave turned on, two base load compressors kicked on to provide the higher CFM usage.

Coppertail Brewery

Coppertail Brewery has been using our Kaeser compressors for some time and have been impressed with our after sales service and support. When they needed a higher quality process chiller, they reached out to us once again. We installed an 80-ton process chiller on their roof which helped them perfect their brewing process and saved thousands in electrical costs.

Mosaic

Mosaic fertilizer company requested a quote for an oilless compressed air system that required stainless steel components and to be skid mounted. Compressed Air Systems was able to win the bid by providing the best solution for their instrument air. Mosaic went on to buy another four units at this specification.

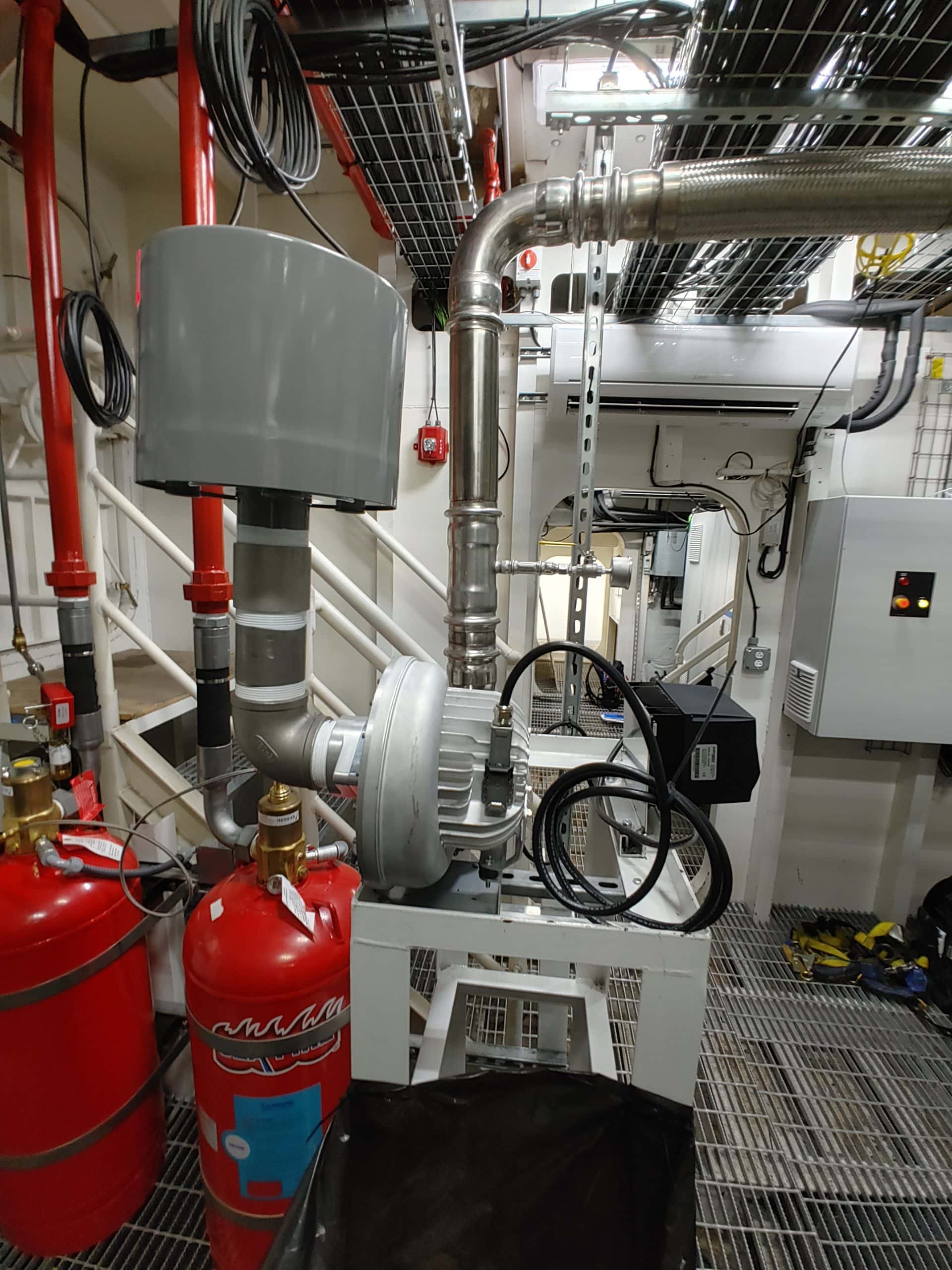

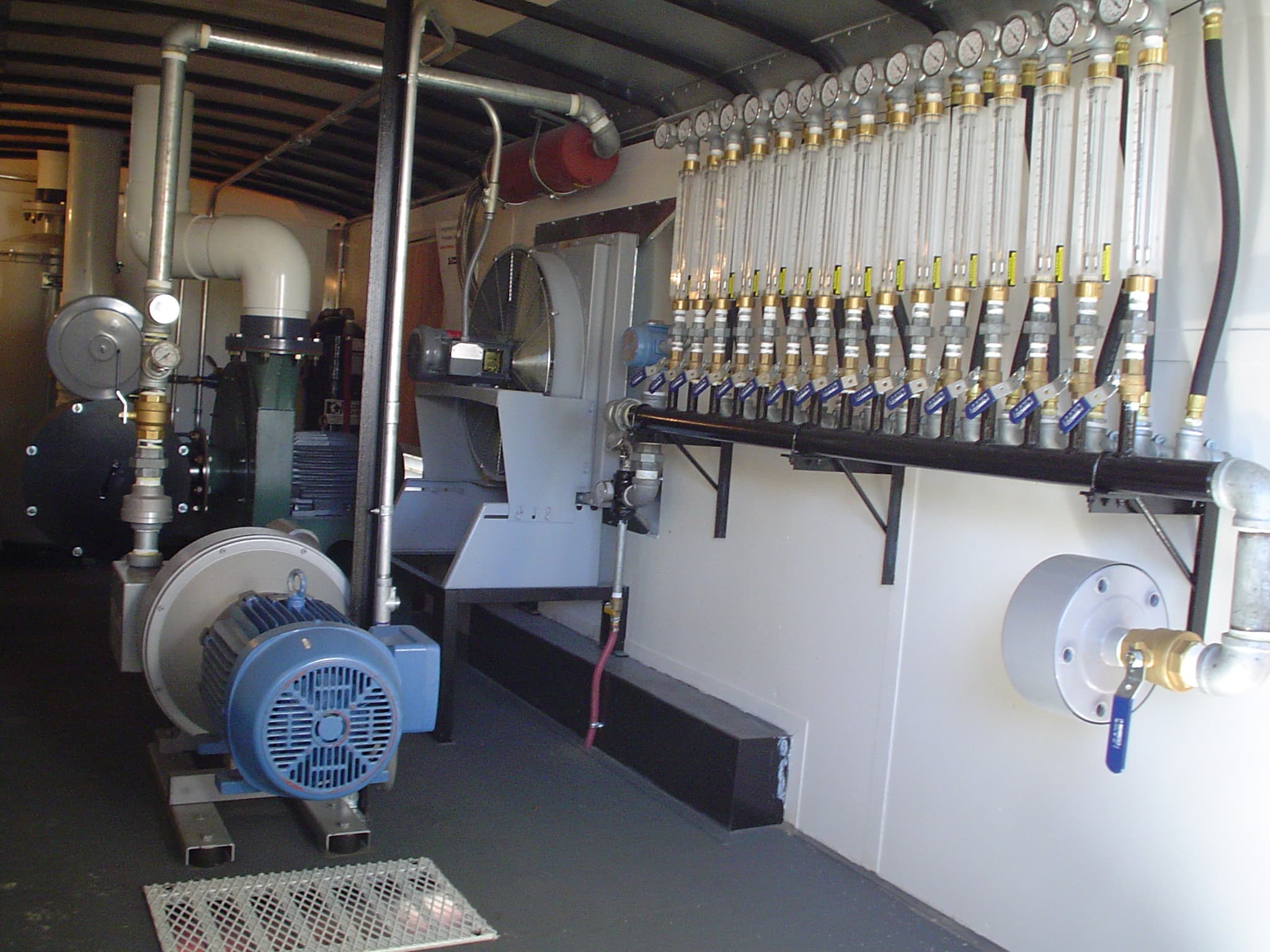

Environmental Remediation

A custom enclosed trailer remediation system was engineered by Compressed Air Systems for a national environmental company. Low pressure compressed air is sent into the separate wells to sparge the product/ fuel, this releasees gases which are then sucked into a vacuum well and sent to carbon containment vessel.