The Role Air Compressors Play in Pandemics

Comments Off on The Role Air Compressors Play in PandemicsClean air is a matter of health even in the best of times, and nowhere is that truer than in the hospital setting where people can be exposed to a wide range of pathogens as they struggle to recover from the ones that brought them there in the first place. Sanitation, from surfaces to the air, is given utmost priority. The respiratory air supplied to patients via machine ventilation has to be completely clean and free from humidity, oil, dust, and pathogens. Hospitals, intensive care units, and emergency rooms rely on medical compressed air every day, and they’ve seen an increased need for it as they treat COVID-19 patients.

These compressed air systems are highly regulated and carefully designed to purify the air even in the most extreme circumstances and environments. They’re trusted around the world, and they are playing an especially vital role during this pandemic.

Do Compressed Air Systems Assist in the Spread of COVID-19?

They’re not helping to spread it—they’re helping to stop it. According to the World Health Organization (WHO), COVID-19 is not airborne. Instead, as was discovered in the early days of the pandemic, it’s spread through the droplets from coughs and sneezes, which can be left on surfaces or spread directly from person to person. There has been no evidence to show that air compressors spread coronavirus, and these machines are still important tools for saving lives in the hospital every day.

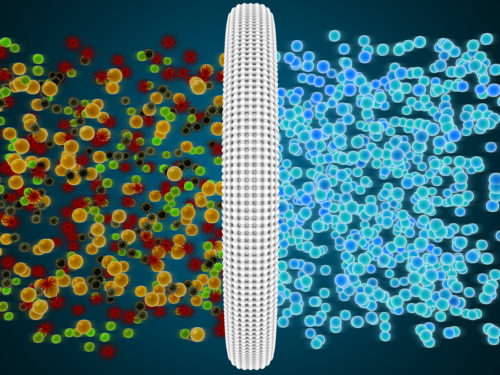

By design, air compression is violent for microorganisms. If viruses and bacteria are present in the air as they enter the compressor, they’re extremely unlikely to survive. This is why:

The air has to pass through panel filters and intake filters when it enters the air compressor. In almost any environment, certainly hospitals included, there are a variety of microorganisms in the air, which is why this inline coalescing filtration is in place. It removes a huge number of contaminants.

The air has to pass through panel filters and intake filters when it enters the air compressor. In almost any environment, certainly hospitals included, there are a variety of microorganisms in the air, which is why this inline coalescing filtration is in place. It removes a huge number of contaminants.

To fight their way through that filtration, contaminants would have to remain in aerosol form, which they would have a hard time doing. During compression, the air is heated to a high temperature very quickly. Depending on the type of compressor, that temperature can go above 300 °F. Even the lower-temp oil-flooded rotary screw compressors are still plenty hot, as they operate at a minimum of 180 °F.

Fortunately, research shows that most coronaviruses die before the temperature gets to 150 °F, and all of them are inactive by 200 °F. The air compressor creates an inhospitable environment for pathogens; the air is clean and clear by the time it reaches the person (in the medical setting) or the product (in the food and beverage industry).

Following Best Practices

As with any piece of equipment, air compressors have to be carefully maintained to continue working properly. To that end, a strict maintenance program is required for all compressed air systems used in food and pharmaceutical applications.

During the pandemic, as during more typical times, these maintenance procedures remain the same. Shutdowns should not be an excuse to postpone necessary inspections and repair. Because air compressors are essential, the mechanics who service them are essential, too, and you still have access to these professionals.

Using only proprietary spare parts and performing proper upkeep for the system will ensure the filters are working as they should, and COVID-19 and other pathogens will not be able to pass through the compressed air. Work with a trusted mechanic to ensure your air compressors are in top condition.

Contact Us for the Air Compressors You Need During This Time

Since 1963, Compressed Air Systems has been serving Florida with air compressor inspection, repair, maintenance, and installation. In that time, we’ve worked on a variety of air compressor models from all the leading brands, and we’ve built long-lasting relationships with customers who rely on compressed air to do their jobs safely and effectively.

When the government awarded a ventilator project to General Motors, the company reached out to us to provide compressed air breathing filtration packages. We were proud to work with GM and contribute to the fight against COVID-19, and, thanks to our years of experience, we were able to provide a quick solution for this critical endeavor. We stand ready to rise to the challenge if and when we can offer more assistance.

If you have any questions about air compressors in general or about the role they play during pandemics like COVID-19, please contact us. Compressed Air Systems is here to ensure the longest possible life for your air compressor.