Industrial Air Compressors

Industrial air compressors are versatile pieces of equipment that provide pressurized air for several industrial processes. When choosing an air compressor for an application, it is important to make sure the selected unit can deliver the desired results while keeping maintenance and operating costs low. The best air compressor for a given application will depend on several factors, including its intended use, the tools or processes it will support, and the project’s budget. Ultimately, your decision should be guided by careful consideration of your performance requirements and available resources rather than simply purchasing the least expensive or most powerful option.

Industrial Air Compressor Selection Process

As you navigate the selection process, the following factors are important to keep in mind:

Industrial Air Compressors from Compressed Air Systems

Compressed Air Systems offers an extensive selection of industrial-grade air compressor units designed to fit the needs of various operations. As an authorized Kaeser dealer, we stock a complete line of high-quality air compressor units in a range of sizes, makes, and models. Options include:

Low Pressure

Low Pressure

Common Industrial Air Compressor Applications

Often referred to as the fourth utility, compressed air keeps vital operations running smoothly and efficiently in several key industries. Having access to a reliable, continuous supply of compressed air can be as critical to a manufacturing plant’s daily activities as electricity, water, and gas. Industrial air compressors are designed to deliver a steady stream of compressed air while providing the durability to satisfy the demands of modern manufacturing operations. These units are integral to several manufacturing applications, including:

Types of Industrial Compressors

Industrial air compressors have become increasingly specialized to perform specific tasks with exceptional efficiency. Below is an overview of the most widely used industrial compressor designs.

Positive Displacement Air Compressors

One of the most common compressor types is the positive displacement air compressor, which is designed to store a certain volume of air in one or more compression chambers. When air is released from the chamber, the compressor responds by increasing the internal chamber pressure until reaching a set pressure ratio. This action facilitates a steady and consistent flow of air.

Two types of positive displacement air compressors used in industrial applications include:

- Rotary screw air compressors: A rotary screw compressor uses a pair of continuously turning helical screws to compress air. It operates by drawing air into the chamber, then reducing the chamber size to compress it.

- Reciprocating/piston air compressors: In contrast to rotary screw compressors, reciprocating air compressors use a series of pistons as the mechanical component. They operate by continually drawing air into a cylinder, then compressing that air using the motion of the pistons.

Two-Stage Air Compressors

Two-stage air compressors operate according to a similar mechanical principle as single-stage reciprocating compressors but with an additional compression step. First, air is pulled into the chamber and partially compressed by the piston. The partially compressed air is then transferred to another chamber, where it is cooled and compressed for a second time. Capable of achieving pressures as high as 500 PSIG, two-stage compressor units are often preferred over single-stage designs in high-capacity manufacturing applications.

Centrifugal Air Compressors

Centrifugal air compressors are among the largest industrial compressors, making them a staple in medium- and large-scale manufacturing plants that rely on a constant volume of compressed air. Typically powered by electricity or steam, these extremely efficient units can handle high capacities, high pressure levels, and heavy use. However, they are generally more expensive and require more specialized maintenance than other industrial compressor types. Given their continuous operation and high rotational speeds, repairs and part replacements can become considerably expensive over time.

High-Pressure Air Compressors

High-pressure air compressors are among the most powerful compressors available, and they are commonly used for breathing air, pneumatics, and paintball equipment. While standard high-pressure compressed air is considered to be anything over 150 PSI, industrial high-pressure air compressors can reach up to 6,000 PSI. This pressure is achieved by cooling the air as it passes through multiple compression stages until it achieves the optimal pressure.

Oil-Free Air Compressors

Most air compressors operate using a piston and cylinder mechanism that takes in ambient air and compresses it into a reinforced tank. With these designs, the walls of the cylinder must typically be lubricated with oil or grease so that the piston operates smoothly.

However, oil-free air compressors have become increasingly popular. These air compressors have cylinders made of naturally lubricating solids like Teflon, removing the need for a lubricant while also improving air purity. Oil-free air compressors operate more cleanly and reliably, require less maintenance, and produce less noise than traditional oil-lubricated compressors.

Food & Beverage Air Compressors

In the food and beverage industry, using high-performance air compressors that produce high-purity air is critical. This is because contaminated air can impede operations and compromise product quality. Unlike other industries where compressed air quality isn’t paramount, compressed air used in food and beverage production (such as in water aeration and food fermentation) must be pure to meet FDA regulations and protect consumer health and well-being.

Compressed Air Systems carries specialized compressed air solutions from brands such as Powerex, Kaeser, and Nano-Purification that ensure compliance with the FDA’s Food Safety Modernization Act (FSMA).

Electric Powered Air Compressors

Ideal for indoor projects, electric-powered air compressors provide the benefits of gas or diesel-powered compressors without any harmful fumes. These compressors are suitable for construction or home remodeling jobs, as they can simply be plugged into an outlet without posing a health risk. In addition, these compressors are much quieter than diesel-powered models.

Dental Compressors

Dental air compressors provide the high-pressure air that powers dental equipment. Dental air compressors need to be able to stand up to the rigors of everyday use without breaking down and causing problems for your office. Compressed Air Systems offers a range of oil-free air compressors and services designed for dental offices.

Breathing Air Filtration

Supplied-air respirators and breathing air filters remove particulates and contaminants from the air in multiple stages. These low-pressure compressed air systems provide a reliable and consistent source of breathing-quality air for workers, particularly in industrial worksites with a high risk of hazardous solid, liquid, or gas inhalation.

Medical Air Compressors

Medical air compressors are vital for hospitals and other medical facilities. These compressors assist patients with breathing, administer anesthesia, and power pneumatic surgical tools. Medical compressors are typically oil-free and must adhere to strict quality and safety standards to ensure that the air is free of harmful particulates.

Portable Air Compressors

Portable air compressors are compact, durable, and easily transportable for mobile or remote applications. These towable air compressors are most commonly used with power tools such as nail guns, hammers, sanders, and tire inflaters.

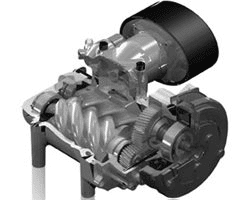

VMAC Underhood Air Compressors

While portable compressors are often an essential tool for contractors, mechanics, and utility workers, they can also be expensive and inconvenient to transport from one site to the next. A VMAC underhood air compressor integrates directly into the design of most work trucks, conveniently installed just under the hood. VMAC compressors run off of the truck’s engine and provide 100% duty cycles for increased productivity.

Contact Compressed Air Systems for Heavy-Duty Industrial Air Compressors

Compressed Air Systems leverages 55 years of experience, cutting-edge air compressor technologies, and collaborative client relationships to deliver optimal performance and reliability for each unique project. Our industrial air compressors are built to handle everything from robust, high-capacity manufacturing operations to smaller-scale commercial and professional applications. With our client-focused and detail-oriented approach, we work hard to make sure that each air compressor unit is built with the needs of your business in mind. Our products are thoroughly tested in-house and independently certified to ensure reliability and compliance.

For more information about our industrial air compressors and other capabilities, please view our catalog or contact us today.