The First Air Compressors

Comments Off on The First Air CompressorsAir compressors are used in a variety of industries to provide compressed and pressurized air for many applications. These devices are now even used to power construction and manufacturing equipment and to drive control system valves, but earlier compressors were much less versatile. The advent of air compressors dates back thousands of years.

The First Air Compressors: Humans?

The earliest air compressor was actually the human lung. Since the human body can exhale oxygen, people once used their breath to stoke fires. The trend of providing our own air pressure faded around 3000 B.C. as the practice of metallurgy became prevalent. Metalsmiths were melting down various materials such as gold and copper, and they soon realized that higher temperatures were needed.

Healthy lungs can only produce .02 to .08 bar (1 bar equates to 14.5 psi) of air pressure—hardly adequate for metalworking tasks. Also, the carbon dioxide content in human breath wasn’t helpful for sustaining fires. The demand for stronger air compressors began to grow as time progressed.

The First Air Compressors: Bellows

In 1500 B.C., a new type of air compressor called a bellows was invented. This device was a hand-held (and later foot-controlled) flexible bag that produced a concentrated blast of air ideal for achieving higher-temperature fires.

The basic design of the bellows has remained unchanged since its invention and can still be found today by fireplaces, inside musical pump organs, and in other devices.

The First Air Compressors: Water Power

During the Industrial Revolution of the eighteenth century, advancements in air compression made it possible for metal mines, factories, and other facilities to increase productivity. In 1762, professional engineer John Smeaton designed a water wheel-driven blowing cylinder that slowly replaced the bellows.

The First Air Compressors: Blasting Machine

Though Smeaton’s device was efficient, it was replaced in turn by the hydraulic blasting machine invented by John Wilkinson in 1776. Wilkinson’s blasting machine became the archetype for later mechanical air compressors.

Air compressors were used for more than just metalworking in those days; they were also used for mining and fabricating metals and providing ventilation to underground areas. During the 1857 construction of the Italy-France rail system, compressors were often used to move large air volumes into the 8-mile construction tunnel. Soon after, people conceptualized more ways to utilize the technology.

The First Air Compressors: Electric Power

By 1800, people began using air compressors to transmit energy. Austrian engineer Viktor Popp created the first compressor plant in Paris in 1888. In just three years, Popp’s 1,500 kW compressor plant grew to 18,000 kW. Another plant was also built at Quai de la Gare. In 1889, Popp attained municipal permission to use his compressed air power network to supply electricity to local generators.

More innovations in air compression continued improving upon the process and soon began incorporating electricity and pneumatic energy.

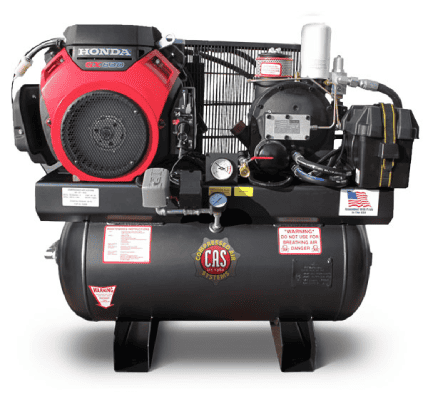

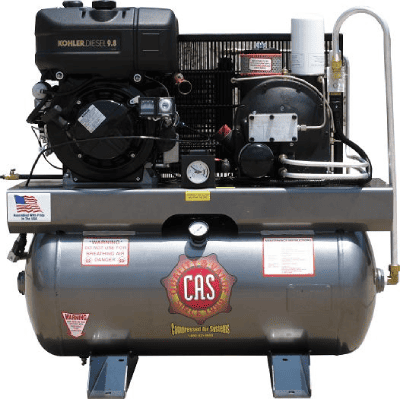

Modern Air Compressors from Compressed Air Systems

Today, there are many types of air compressors to choose from. Compressed Air Systems offers a vast product line of air compressor types that include the following:

- Oil-free

- Reciprocating

- Vehicle-mounted

- Rotary screw

- Electric

- Gas-powered

- Remanufactured

- And more

Whether you’re located in Orlando, Tampa, or outside Florida, Compressed Air Systems can provide quality industrial air compressors and services that meet your unique needs. Browse our catalog, or contact us today to learn more about our air compressors.