Compressed Air System Capabilities for the Plastic Industry

The plastic industry in the United States accounts for $380 billion in shipments every year and has created 885,000 domestic jobs. It’s the third-largest manufacturing industry in the country.

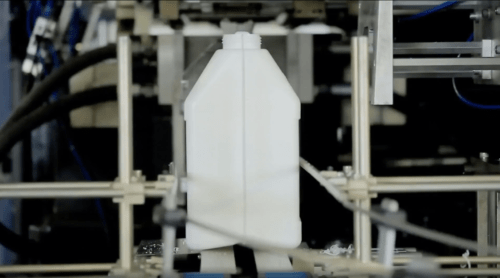

Industry-leading plastic manufacturing plants use air compressors because they are the best at providing precise, reliable, and efficient power to manufacture high-quality plastics safely and consistently. In fact, air compressors have become the standard tool for delivering power.

Why Use Air Compressors in the Plastic Industry?

Plastic manufacturing requires precise operations to ensure the product holds a strong, durable shape. Every facility’s power delivery system must be fine-tuned, so it can operate during delicate stages of the process. At the same time, plastics plants need consistent access to energy-efficient power solutions that allow them to operate within stringent efficiency regulations.

Air compressors strike the balance between three competing requirements in plastic industry facilities: precision, reliability, and energy efficiency.

Precision

While current technology can minimize fluctuations in electrical currents, it can’t stop them entirely. Pneumatic air compressors stabilize the flow of power into equipment and processes by absorbing the fluctuation. Air compressors can also be tightly controlled to deliver precise levels of power and pressure at each manufacturing stage.

Reliability

Air compressors are a main utility for plastic processing plants and having a premium air compressor is worth the investment. Without interrupting production of their compressor air demands, a second compressor is vital for reliability.

For example, in dusty or dirty manufacturing conditions, air compressors can perform more reliably than other tools. A properly maintained air compressor will perform more reliably. They can also maintain consistent performance during temperature fluctuations and adverse weather conditions when properly equipped with correct options.

Energy Efficiency

Due to increasing concerns about energy production, greenhouse gases, and climate change, manufacturing facilities are under intense pressure to operate more efficiently. Air compressors help generate power in a way that is both cost-efficient and compliant with energy consumption regulations.

Finding the Proper Air Compressor for the Plastic Industry

Every plastic manufacturing plant is slightly different and operates in varied conditions, which means they need the right air compressor for their unique solutions. Selecting one while constructing a new manufacturing facility or retrofitting an existing plant for air compression power is absolutely essential to maximize all the benefits of pneumatics.

Some important considerations include:

After the Sale Support

You need an air compressor that is easy to use and shows immediate results after installation. It’s also important to find manufacturers that offer warranties, service guarantees, and support after the initial purchase and installation. Look for manufacturers that:

- Offer diagnostics, support, and maintenance

- Have easy-to-reach customer service lines

- Have a wide distribution network for parts and servicing

Quality Construction

Air compressors need to have high-quality construction to remain durable and energy-efficient throughout years of industrial use. They need:

- Innovative design

- Totally enclosed fan cooled (TEFC) motors with class F insulation

- Service friendly construction

- Guaranteed efficiency

- Magnetic wye-delta reduced voltage starting

- Efficient separator system

- Low sound and vibration

- CAGI (Compressed Air & Gas Institute) certified performance

- Monitoring and maintenance controllers

Looking for well-made air compressors, even if they have a higher initial cost, can save your facility time and money on repairs, downtime, leakages, and energy waste.

Smart Analytics

No matter how large your facility is, employing your air compressor with smart analytics technology can help it stay on top of potential malfunctions, leaks, and surges in energy consumption. Smart systems gather data about:

- Potential areas with wasted electrical use

- Developing strains in the system

- Aggregate electrical consumption to ensure your facility is staying compliant with energy use regulations

Contact Compressed Air Systems Today to Learn More

If you’re constructing a new plastics manufacturing facility or retrofitting a plant to use air compressors, contact Compressed Air Systems today. Our team will help you find the best air compressor and control systems for your needs.